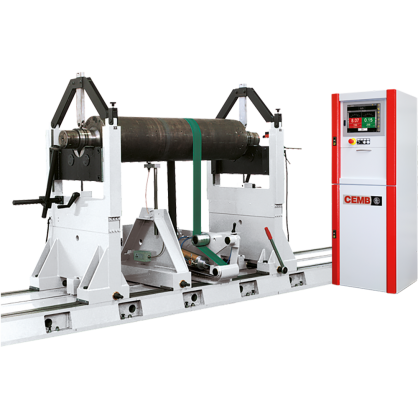

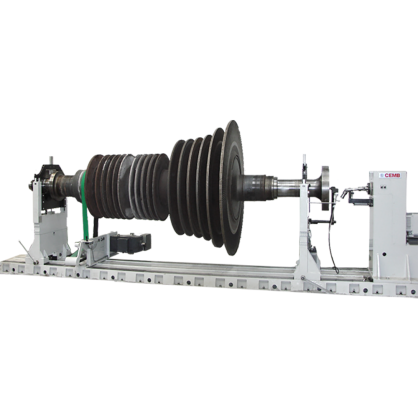

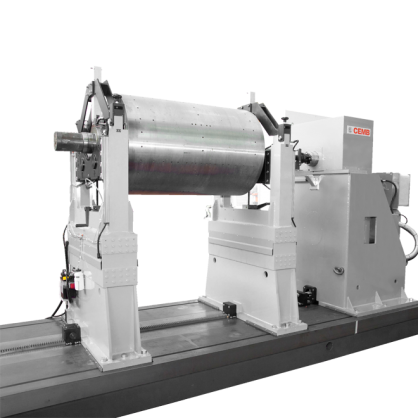

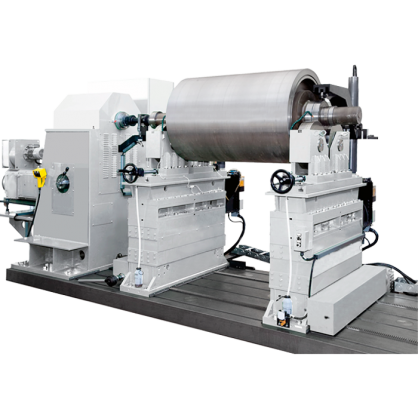

Horizontal Balancing Machines

UK’s Leading Dynamic Balancing Expert

Cemb Hofmann UK’s horizontal dynamic balancing machines are fitted with the latest ‘touch screen technology’ and offer some of the fastest and most high precision horizontal dynamic balancing machines on the market. Driving productivity and boosting profit is central for manufacturers in today’s highly competitive industry. Providing balancing machines that optimise performance, enhance the lifespan of components and minimise downtime is critical to success.

Reducing machinery energy consumption

As the provider of a world-class sub contract dynamic balancing service, our reputation has been built on unrivalled experience in the industry. In this environmentally conscious age, we are happy to say that our balancing systems are particularly effective at reducing the energy consumption of our customer’s machinery, as well as minimising noise pollution.

From the manufacture of our first balancing machine in 1946, to the breakthroughs in technology that have been made in the last decade, Cemb Hofmann UK is undoubtedly the leading balancing expert in the UK.

- All

- Weight from 0 to 500 Kg

- Weight from 500 to 10000 Kg

- Weight from 10000 to 60000 Kg

Fast and accurate horizontal axis hard bearing dynamic balancing machines suitable for measuring static and dynamic unbalance and suitable for rotors that weigh from 1g to 100 tonnes.

Improve the service life, quality and accuracy of your machinery by addressing unbalanced parts promptly and with the most up to date, high precision dynamic balancing machines on the market.

If you are interested in outsourcing your balancing requirement then why not discover more about our renowned sub contract dynamic balancing service which can save you both time and money as well as ensuring that your machinery is in the hands of the leading balancing expert in the UK.

Features List:

- Windows operating system with easy to follow instructions.

- Fast and accurate results first time.

- Operator assisted correction programs for removing and adding material.

- No calibration – just enter rotor dimensions and balancing grade or tolerance.