In industrial settings, unplanned downtime is more than an inconvenience.

It’s a costly threat to productivity, safety, and customer satisfaction.

That’s why forward-thinking manufacturers are shifting from reactive maintenance to predictive strategies, and at the heart of this transformation lies vibration analysis and monitoring.

We offer a range of vibration monitoring systems and portable diagnostic tools that give maintenance teams the insight they need to detect issues before they become failures.

In this blog we explore how vibration analysis works, why it’s critical for machine health, and how it can help you optimise maintenance, reduce costs, and improve reliability across your operation.

What is vibration analysis?

Vibration analysis involves measuring the oscillations of rotating or moving machinery to detect imbalances, misalignments, looseness, or wear. Each of these issues has a unique vibration signature that, when correctly interpreted, can give a clear picture of the machine’s condition.

By monitoring this data in real time or at regular intervals, engineers and maintenance personnel can spot early signs of deterioration and intervene before major damage or downtime occurs.

Why vibration monitoring matters

Rotating machinery is at the core of most industrial processes (pumps, fans, motors, turbines, compressors, and more).

Any imbalance or fault in these components can lead to:

- Mechanical failure

- Unplanned downtime

- Increased energy consumption

- Safety risks

- Reduced output quality

By implementing a vibration monitoring system, you shift from a “fix-it-when-it-breaks” approach to a proactive strategy that protects productivity and cuts unnecessary repair costs.

Vibration monitoring systems

We supply a complete portfolio of vibration analysis and condition monitoring solutions, including:

Portable vibrometers & balancers

Ideal for maintenance and field teams, these rugged, easy-to-use devices allow for:

- Single or two-plane balancing

- Real-time FFT (Fast Fourier Transform) analysis

- Smart diagnostics and trend tracking

- Use on motors, pumps, compressors, fans, and more

These tools are perfect for service departments, repair shops, and technicians who need powerful diagnostics on the move.

Online vibration monitoring systems

For critical assets and 24/7 production environments, our online systems offer continuous monitoring and real-time alerts. They include:

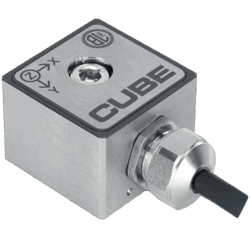

- Vibration sensors and transmitters

- Integrated monitoring software

- Alarms for unbalance, misalignment, bearing wear, and structural looseness

- Customisable thresholds for specific machines

These systems are essential for industries like power generation, oil and gas, chemical processing, and any application where equipment failure has major implications.

Benefits of predictive maintenance through vibration analysis

1. Early fault detection

Catch issues before they escalate into failures or safety concerns.

2. Extended equipment life

Well-balanced and monitored machinery lasts longer and performs better.

3. Reduced downtime & repairs

Plan maintenance around actual need, not manufacturer intervals or guesswork.

4. Lower maintenance costs

Avoid unnecessary part replacements and emergency repairs.

5. Improved production quality

Less vibration means tighter tolerances, smoother operation, and better finished products.

6. Data-driven decisions

Use historical vibration trends to make smarter, more strategic maintenance plans.

Industries that benefit most from vibration monitoring

While all industrial sectors can benefit from vibration analysis, it’s particularly valuable for:

- Manufacturing & Processing Plants

- Automotive Production Lines

- Power Generation Facilities

- HVAC and Utility Systems

- Repair Workshops and Service Teams

- Marine and Offshore Operations

Why choose us for vibration analysis?

- Decades of experience in balancing, diagnostics, and industrial machinery

- Smart, intuitive tools designed for real-world users, from technicians to engineers

- UK-based support, service, and calibration

- Tailored solutions for portable use, continuous monitoring, or integration into your condition monitoring strategy

For further information about vibration monitoring please explore our range here.