In high-volume manufacturing environments, balancing is a fundamental part of maintaining efficiency, product quality, and profitability. For manufacturers seeking to automate the balancing process without compromising on accuracy or control, production balancing machines can deliver the perfect solution.

Whether you’re producing thousands of components per day or looking to reduce cycle times and human error in your process, our range of automatic and semi-automatic production balancing systems are designed to meet the highest demands of modern industry.

In this blog, we explore how production balancing machines work, what applications they are best suited for, and why they’re critical to modern production environments.

Why automate the balancing process?

Manual balancing is highly effective, but in production environments where speed, repeatability, and output consistency are critical, it can quickly become a bottleneck.

Automating the balancing process enables manufacturers to:

- Eliminate variation caused by manual handling

- Minimise the risk of operator error

- Significantly reduce cycle times

- Achieve consistent balance quality across large batches

- Improve operator safety and ergonomics

- Seamlessly integrate quality control into production lines

The results are greater efficiency, better margins, and higher product reliability.

What are production balancing machines?

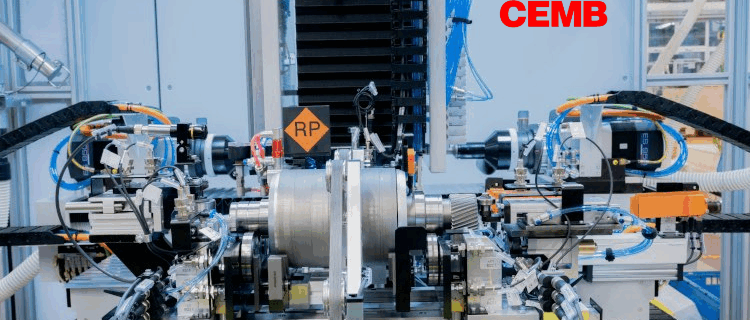

Production balancing machines are specially designed systems that balance rotating components automatically and often as part of a continuous flow within a manufacturing line.

Semi-automatic systems

• Require operator loading/unloading

• Feature automatic measurement and correction

• Ideal for mid-volume applications where precision and speed are still priorities

Fully automatic systems

• Integrate fully into production lines

• Include automatic part loading, clamping, unbalance correction (e.g., drilling or milling), and unloading

• Deliver the highest throughput with minimal operator involvement

Our knowledge and application experience means that we also offer customised automation options for complex part geometries and specialised correction techniques, helping you meet tight tolerances with total confidence.

Ideal applications

Our production balancing machines are widely used across industries where high throughput and tight tolerances are essential:

• Automotive manufacturing (crankshafts, clutch assemblies, flywheels)

• Electric motor production (rotors, fans)

• Aerospace components

• HVAC and white goods

• Power tools and rotating assemblies

From small component balancing to large and complex parts, our machines are built for speed, repeatability and integration.

Features that maximise ROI and minimise downtime

While investing in automated balancing is not to be taken lightly, it delivers a rapid return when the right features are built into the system:

• High-speed measurement and correction for ultra-fast cycle times

• Integrated unbalance correction (milling, drilling, or material addition)

• Touchscreen control systems with easy-to-use interfaces

• Full diagnostic and reporting functionality for quality traceability

• Remote support options for rapid troubleshooting

• Customisable guarding and safety systems for compliance and protection

With every system, we aim to reduce the cost per balanced part while maintaining the highest standards of precision.

Seamless integration with your production environment

Our production balancing machines are engineered to integrate seamlessly into your existing workflows. Whether you’re setting up a new production line or upgrading an old one, our team will help you:

• Define the right balancing process

• Design the machine layout and interface

• Optimise for automation, space, and output goals

• Train your operators and support ongoing performance

With decades of experience in both the engineering and software sides of balancing systems, we are your trusted partner for smooth and scalable implementation.