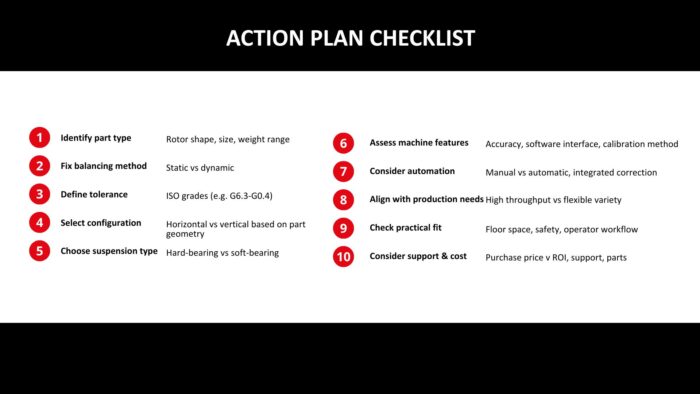

1. Define the part type you need to balance

- Is it a rotor, flywheel, crankshaft, fan, brake disc, train wheel, or pump impeller?

- Weight ranges can vary dramatically, from grams to tens of tonnes. Our horizontal machines, for example, handle rotors from 1 g to over 100 tonnes.

2. Choose the appropriate balancing method: static vs dynamic

3. Determine acceptable balancing tolerances

4. Match component specifications: size & weight range

Horizontal vs vertical: Horizontal machines are ideal for long, heavy components, whereas vertical machines suit shorter, disk-shaped rotors. The choice between horizontal and vertical configurations not only reflects the geometry of the part but also influences ease of loading, cycle times, and integration into production workflows.

5. Hard-bearing vs soft-bearing: which suspension type?

6. Evaluate machine features & performance

- Accuracy & repeatability: essential for reliable balancing outcomes.

- Ease of setup: hard-bearing machines minimise calibration; operator-assisted software simplifies inputting rotor dimensions and balancing grade.

- Operating platform: Windows-based systems with intuitive interfaces, automatic correction prompts, designed for speed and usability.

7. Automation & balancing technology

8. Match production type: volume & variety

9. Practical & service considerations

Machine configuration:

Choose between horizontal, vertical, semi-automatic, or fully-automatic based on part geometry, plant layout, and throughput needs.

Space and layout:

Account for footprint, access for loading/unloading, and integration with existing workflows. Our models vary widely, from compact to very large capacities.

Safety features: Protective enclosures, emergency stops, interlocks, all vital for operator safety and compliance.

10. Commercial factors: cost and support

Initial purchase cost:

High-precision machines require investment, but deliver ROI via extended component life, reduced downtime, and superior product quality.

Support & service availability:

We provide UK-based technical support, calibration, maintenance, upgrades, and even subcontract balancing services.

Spare parts & maintenance:

Availability of parts and local service ensures minimal operational interruptions.

Why choose CEMB Hofmann?

Broad machine range:

From gram-scale rotors to 60-tonne components, in horizontal and vertical setups.

Hard-bearing, permanent calibration:

Fast, intuitive balancing, even across varying rotor types.

User-friendly Windows interface:

Minimal setup, assisted correction programs and no routine calibration required.

UK-based expertise & service:

Technical support, spare parts, machine upgrades, subcontract balance solutions, dynamic balancing resources.

Final thoughts

Selecting a balancing machine is a strategic technical and operational decision. Understanding your rotor types, balancing precision, and production needs is essential.

Our flexible, high-precision machines, combined with expert local service, make us a compelling choice for any engineering or manufacturing scenario.