In any industrial setting, imbalance is a silent threat. It leads to excessive vibration, increased wear, energy loss, and, ultimately, machine failure.

Correcting that imbalance through precision dynamic balancing restores smooth operation, improves performance, and extends component life.

But when imbalance occurs, or when new rotors are ready for use, there’s an important decision to make: should the balancing be done on-site (field balancing) or in a workshop (shop balancing)?

Both methods have clear advantages depending on the situation. At CEMB Hofmann UK, we provide both field and shop balancing services, helping customers select the most efficient and cost-effective solution for their needs. Here, we take an objective look at the two approaches and where each delivers the greatest value.

What is field balancing?

Field, or in-situ, balancing is performed on the customer’s site while the rotor remains installed. Using advanced portable analysers such as the CEMB N330, engineers can measure and correct imbalance without removing the component from its housing.

This approach is especially useful for large or fixed installations, or for time-critical projects where removing and transporting the equipment would cause unacceptable downtime.

Typical examples include:

- Ventilation fans and blowers

- Hammer mills

- Pumps, turbines, or other plant equipment operating in place

Modern field balancing equipment such as the N330 offers impressive precision. It uses the same algorithms found in workshop machines and can achieve ISO balancing grades when configured with the correct parameters, such as service speed, balancing grade, overall mass, foundation type, and drive-motor characteristics.

An additional advantage of the N330 is its Smart Analysis function, which helps identify whether vibration is caused by imbalance, misalignment, or looseness—making diagnostics faster and more reliable, even for operators without deep vibration-analysis expertise.

Key advantages of field balancing

- Minimal downtime: no need to dismantle or transport machinery.

- Real-world accuracy: balancing under actual operating conditions.

- Versatility: suitable for a wide range of installations.

- Diagnostic capability: advanced analysers can distinguish vibration causes.

Limitations

- Accessibility: physical access to the component may be restricted.

- Environment: heat, dust, or hazardous materials can make on-site work impractical.

- Cost factors: time spent on-site—especially where multiple runs are needed—can exceed workshop costs.

What is shop balancing?

Shop balancing, sometimes called sub-contract balancing, is performed in a controlled workshop environment using dedicated horizontal or vertical balancing machines.

This method is ideal when components are brand new, spares, or undergoing overhaul, and when high-precision tolerances are required. It also enables batch balancing, making it efficient for OEMs and maintenance providers handling multiple parts simultaneously.

Because the work is carried out in a stable environment, external influences such as vibration, temperature, or access constraints are removed. This ensures maximum repeatability and compliance with relevant ISO standards.

Our sub-contract balancing service is a prime example of this capability. Components are delivered to our fully equipped workshop in the UK, where trained engineers use calibrated CEMB machines to balance parts to the highest tolerances. Once complete, items are returned ready for installation or distribution.

Key advantages of shop balancing

- Controlled environment: eliminates external interference for highest accuracy.

- Batch efficiency: multiple parts can be balanced within planned timeframes.

- ISO compliance: work performed to international precision standards.

- Traceability: documentation and reporting available for quality assurance.

Limitations

- Downtime: requires removal, transport, and reinstallation of the rotor.

- Less “real-world” context: conditions in the workshop differ from those in service.

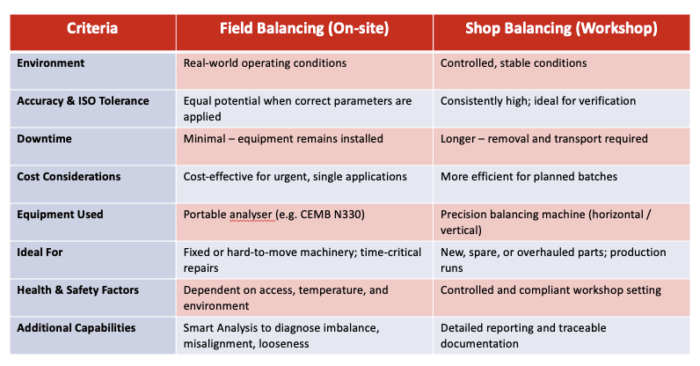

Field vs shop balancing: side-by-side comparison

How we advise on the right approach

Every balancing project begins with a conversation. Our team first assesses:

- The component’s operating speed and balancing grade

- Its overall mass and foundation type

- The drive-motor configuration and environmental constraints

Using this information, we work with our customers to determine the safest and most cost-effective approach. If access or heat pose a risk, or if materials being processed are hazardous, the team may recommend removing the component and using our sub-contract workshop service.

Conversely, when downtime must be minimised or equipment cannot be transported, our engineers can provide a full on-site field balancing service, complete with diagnostic support.

It’s this flexible, consultative approach that allows CEMB Hofmann UK to deliver balancing precision wherever it’s needed, whether in the field or at our Manchester facility.

Precision wherever you need it

In truth, there’s no universal “better” method. Both field and shop balancing can achieve excellent results when performed correctly and to ISO standards.

Field balancing provides the convenience and realism of in-situ correction, while shop balancing offers unmatched control and repeatability. The right choice depends on your component, your schedule, and your operational environment.

Whatever the requirement, we combine decades of experience, advanced technology, and proven expertise to keep your machinery running smoothly, whether on-site or in our workshop.