When precision matters, sub-contract balancing provides an efficient and cost-effective way to achieve smooth, reliable performance in rotating components. In this guide we explain what sub-contract balancing is, when to use it, and how to choose the right partner to help you make informed decisions that improve machinery performance, safety, and longevity.

Why sub-contract balancing matters

In industries where rotating components are fundamental, such as automotive, aerospace, power generation, and manufacturing, precision balancing is essential for performance, efficiency, and reliability. An imbalance in a rotating part can cause excessive vibration, noise, and wear, leading to downtime, higher maintenance costs, and premature equipment failure.

However, not every company needs or wants to invest in its own balancing equipment and that’s where sub-contract balancing comes in.

By outsourcing balancing to a specialist, you gain access to expert engineers, advanced machinery, and fast turnaround times and all without the cost and complexity of maintaining your own balancing facilities.

What is sub-contract balancing?

- Electric motor rotors

- Fans and impellers

- Pumps and compressors

- Turbines

- Armatures and generators

- Clutches and couplings

- Brake discs and flywheels

Use cases for sub-contract balancing

Sub-contract balancing is particularly valuable when:

Production volumes fluctuate

Outsourcing avoids idle investment in balancing machines during low-demand periods.

Component types vary

A specialist partner can handle different sizes, shapes, and weights on multiple machines.

Tight tolerances are required

Expert balancing facilities can achieve precision levels in line with ISO 1940/1 and other standards.

You’re developing prototypes

During design and R&D phases, it’s more practical to sub-contract balancing until volumes justify your own machine.

Your in-house machine is offline

Outsourcing provides continuity while equipment is being serviced or upgraded.

You want independent verification

Using a certified balancing service can validate or diagnose production issues.

The sub-contract balancing process

Understanding balancing grades and standards

- G6.3 – typical for general machinery and fans

- G2.5 – common for electric motor rotors

- G1.0 – used for high-speed turbines and precision components

Choosing the right sub-contract balancing partner

Selecting the right provider can make the difference between smooth operations and recurring vibration problems. When evaluating a potential partner, consider:

1. Experience and expertise

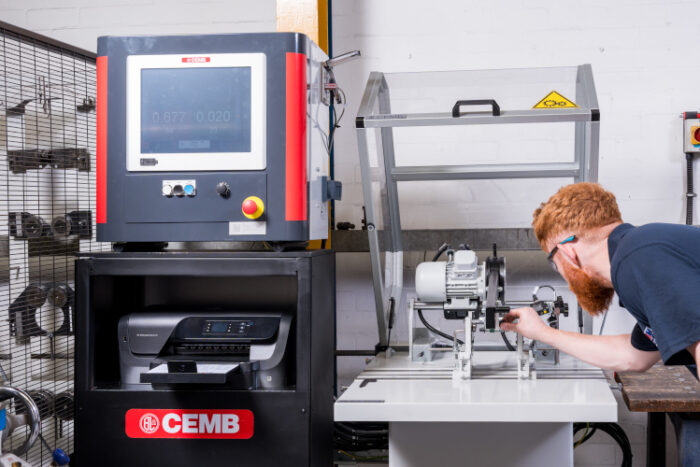

Look for a company with decades of practical experience, ideally across multiple industries and component types. CEMB S.p.A for instance, for whom we are the UK operation, has been a leader in balancing for over 75 years.

2. Machine capability

Ensure the provider’s machines can accommodate your parts’ weight, size, and configuration. Our workshop handles everything from small rotors to components weighing several tonnes.

3. Calibration and certification

Confirm that all machines are regularly calibrated and traceable to national standards. The facility should also operate under a recognised quality management system.

4. Speed and flexibility

A good partner will offer fast turnaround times, often within 24 to 48 hours, and the flexibility to handle urgent or one-off jobs.

5. Technical support

The best providers act as technical partners, not just service suppliers. They’ll help diagnose vibration issues, recommend balance tolerances, advise on design improvements and always be able to offer expertise for your specific application.

6. Confidentiality and care

If your parts are proprietary, confidentiality and careful handling are essential. Always choose a company that protects your designs and components as if they were their own.

The benefits of sub-contract balancing

Working with a specialist like CEMB Hofmann UK brings several key advantages:

No capital investment

Avoid the cost of purchasing, maintaining, and staffing a balancing machine.

Access to advanced technology

Use the latest, high-precision balancing systems and analysis equipment.

Consistent quality

Every part is balanced to certified standards by experienced technicians.

Reduced downtime

Outsource balancing to maintain production flow while machines are serviced or to meet demand peaks.

Independent verification

Get objective data and certification for customer assurance or compliance purposes.

Nationwide service

We serve customers across the UK, offering quick turnaround and reliable logistics support.

Why choose CEMB Hofmann UK

- Horizontal and vertical machines covering a wide range of component sizes

- Static and dynamic balancing to ISO 1940/1 and custom specifications

- Single- and two-plane balancing

- Specialist fixtures and tooling for complex geometries

- Full reporting, certification, and data traceability

- Fast turnaround, including same-day and next-day service when required